Penybont WwTW

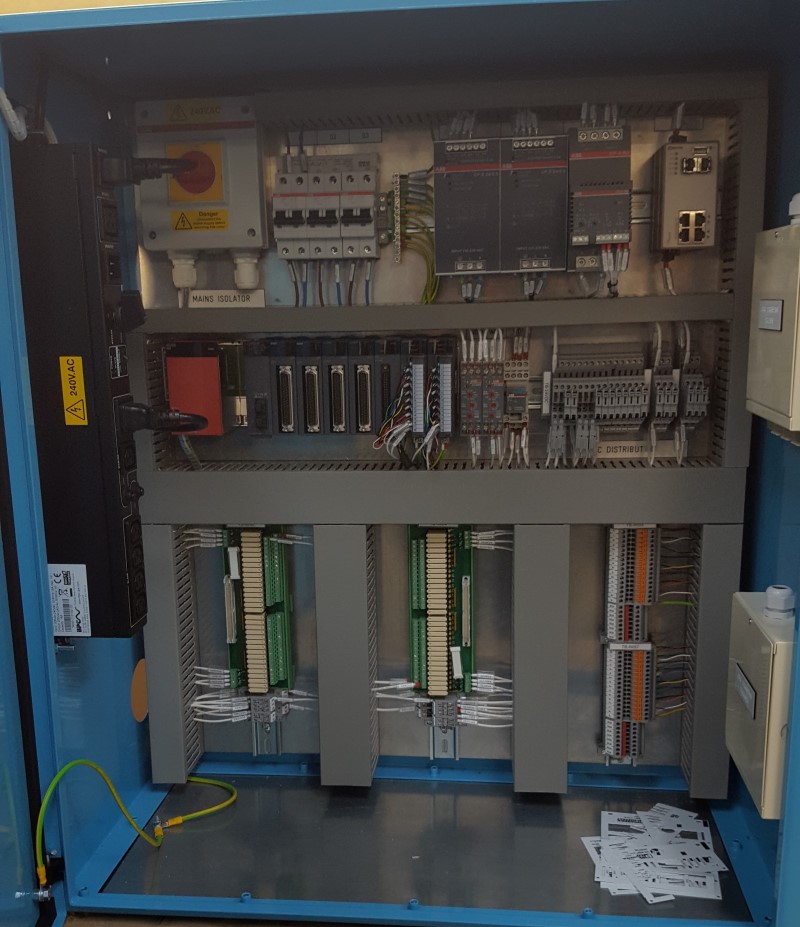

OSS successfully tendered the contract providing Full CDM project with OSS as Principal Contractors to Design and Panel build the main PLC cabinet, server cabinet and two smaller ICA panels and modify a further ten existing ICA panels on site.

More details on the project can be found on the following link:

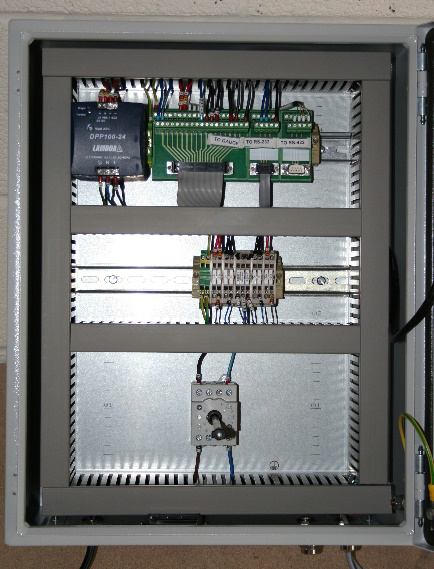

Limab Laser Panel

OSS was engaged to build this laser length measurement panel and control box to the client’s design.

OSS built a CE marked control panel to specific customer requirements, to comply with all legal requirements and to conform to relevant industry standards, including BS EN 61439. In addition, we used our in-house design and manufacture capabilities to deliver a solution that is fit for purpose and is of good quality and value.

More details on the project can be found on the following link:

Maerdy WTW Process Improvements

The existing chlorination system was replaced with a bulk delivery hypo and batching system.

The flow control through the works was reviewed and improvements identified and implemented.

The addition of a Run to Waste to allow for process stabilisation for overcoming poor quality conditions.

How Did We Stand Out? In a post project review by the Principal Contractor, MMB, it

was communicated back to OSS that we were the only sub-contractor to gain full marks in respect to the assessment of

performance on the scheme.

More details on the project can be found on the following link:

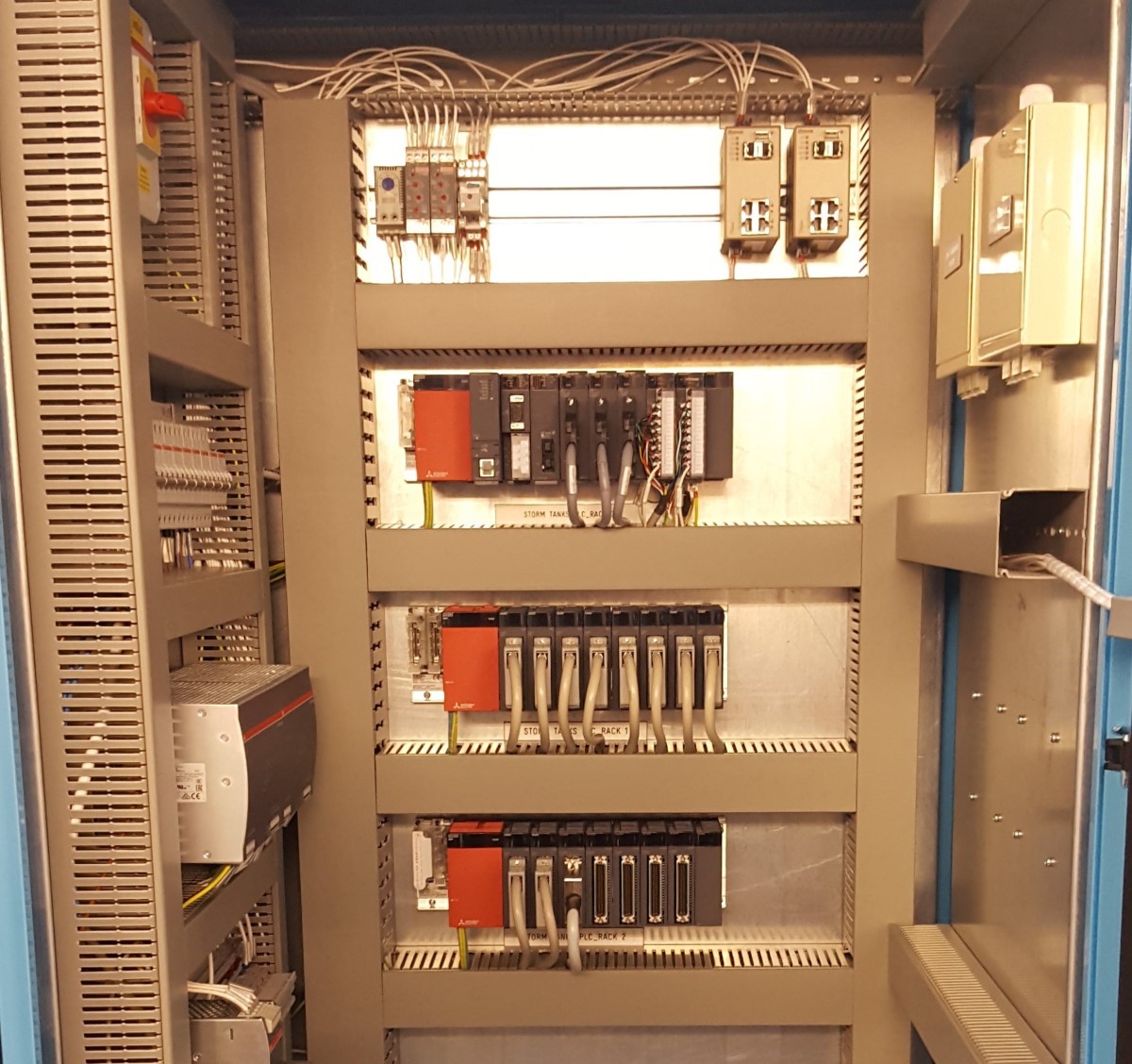

Prioress Raw Water Pumping Station

The fully automated raw water pumping station is situated on the bank of the River Usk and abstracts up to 318 million litres of water a day to supply the Llandegfedd reservoir whilst protecting the fish species that spawn within the River Usk.

OSS successfully completed the system integration of the new control system, a PLC/SCADA solution using Mitsubishi Q series redundant PLCs connecting to multiple Profibus networks to control and monitor a variety of intelligent devices including Siemens Medium Voltage Variable Speed Drives, visualised with a Servelec SCADA and telemetry system.

More details on the project can be found on the following link:

Penybont WwTW

OSS successfully tendered the contract providing Full CDM project with OSS as Principal Contractors and to migrate the existing control system to a new PLC/SCADA solution using Mitsubishi Q series PLCs and a Servelec SCADA and telemetry system.

More details on the project can be found on the following link:

Cefn Dryscoed WTW

OSS successfully tendered the contract to migrate the existing SATT control system to a newer modern PLC/SCADA solution using Mitsubishi Q series PLCs and a Servelec SCADA and telemetry system.

More details on the project can be found on the following link:

Mayhill WTW

We were very proud of our team who worked around the clock to help Dwr Cymru Welsh Water return Mayhill WTW in Monmouth, back into service following the terrible flooding caused by Storm Dennis. The project outcome was a demonstration of collaboration and commitment from several key contractors, working together to help out in this emergency.. More details on the support provided can be found on the following link:

VIEW PDF

Alwen WTW

OSS worked closely with Black & Veatch, on behalf of DCWW, to deliver a new Rapid Gravity Filtration Plant at Alwen WTW in Deeside, North Wales. The existing SIEMENS APACS Control system with PCS7 OS SCADA was expanded to include a new control system node and SCADA client. The project was delivered within tight timescales and close liaison with the other disciplines on the scheme was essential. More details on the scheme can be found on the following link:

VIEW PDF

Cwellyn WTW

New Dissolved Air Floatation and Rapid Gravity Filtration plants were built and constructed at Cwlleyn WTW in the heart of Snowdonia. OSS provided the expertise to develop and commission the APACS/PCS7 OS control system software to meet the DWI date. It was a highly successful project, resulting in an award for OSS from the AMA alliance. Details of the case study can be found within the following Water Projects Online article:

VIEW PDF

Llyn Conwy WTW

Under the Black and Veatch Go to Green programme, the control system at Llyn Conwy WTW was migrated to the new Mitsbushi Servelec solution to align with DCWW's Automation strategy. A technically challenging project, OSS were drafted in to assist with the development and commissioning of the new system control system working closely with MCC suppliers GPS, to get the project delivered to the satisfaction of all parties. Details can be found on the following link

VIEW PDF

Mynydd Llandegai WTW

Mynydd Llandegai WTW was expanded to include a CocoDaff plant to address water quality issues from the raw water supply. Following on from a successful Siemens PCS7 control system migration project towards the end of 2009, OSS were contracted to extend the control system to include a number of intelligent MCCs and Profibus instrumentation networks. The new plant was successfully commissioned in isolation before being integrated within the mains works simply by adding the new Profibus networks to the existing AS controller. The project was a great demonstration of innovative use of technology to mitigate disruption to existing plant operations. A detailed case study can be read here:

VIEW PDF

Maple Brook Pump Station

As part of the refurbishment programme of Maple Brook Pump Station, OSS's electrical division undertook the electrical installation contract, working closely with Imtech Process on behalf of South Staffs Water. Further details of the scheme can be found here:

VIEW PDF

Nantybwch WTW

A water treatment works (WTW) in South Wales has had its control system completely upgraded, without disruption of supply to the population of around 70,000 people it serves.

VIEW FULL CASE STUDY